1、 Definition of hot stamping process:

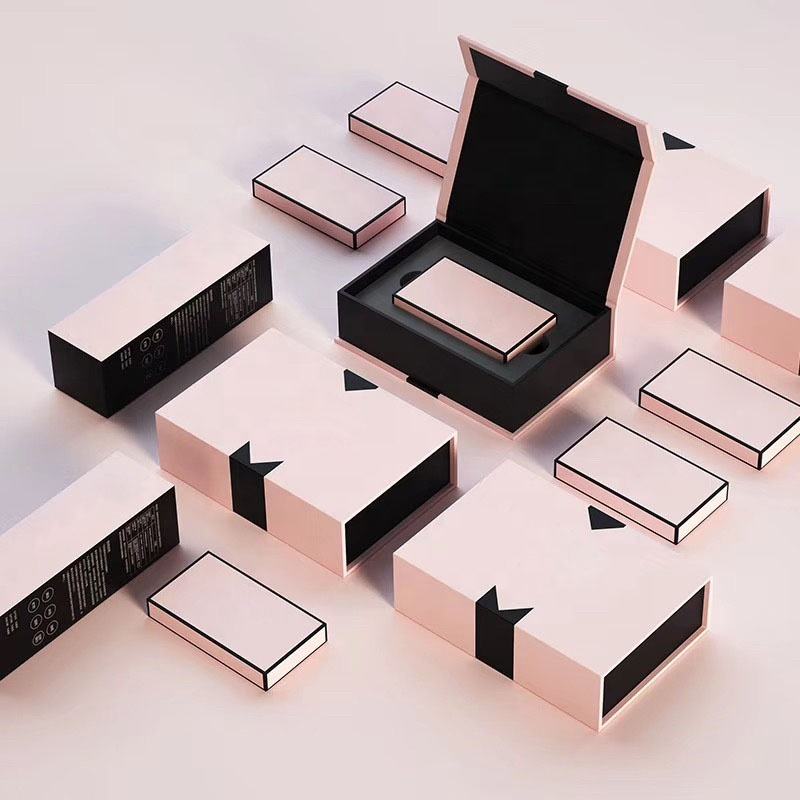

Hot stamping process: It is the process of using metal foil and transferring it to the surface of printed matter or other items through hot pressing to increase the decorative effect.

Cold stamping process: It is a process of transferring metal foil onto the surface of printed matter or other items without heating, only through pressure and the force of adhesion and peeling, to achieve decorative effects.

2、 Purpose of hot stamping:

A metal texture pattern that allows the printing surface to have multiple colors simultaneously, and can also combine different hot pressing effects. In addition to its surface decoration function, hot stamping also plays an important role in anti-counterfeiting.

3、 Advantages and disadvantages of hot stamping process:

1. Advantages:

(1) Full face hot stamping products, without ink residue;

(2) No unpleasant odors such as ink, and no air pollution;

(3) Colorful patterns can be hot stamped at once to reduce wear and tear;

(4) The process is simple, production management and process actions are smooth, and the product quality insurance coefficient is large;

(5) Wide processing range, suitable for paper, wood, plastic, leather, etc.

2. Disadvantages:

(1) Not suitable for substrate with uneven or matte surface during hot stamping;

(2) Metal, glass, ceramics, nylon and other products are generally not suitable for hot stamping, unless they are first painted or screen printed;

(3) Matching of pattern color with workpiece background color: During hot stamping, the color of anodized aluminum (gold, silver, copper, inner red, inner blue) has a strong covering power, and even if the workpiece background color is black, it can be completely covered; But when using transfer paper with lighter colors such as white and yellow on a black background for hot stamping, its covering effect is not as good as that of transfer printing or screen printing.

4、 Classification of stamping process:

1. The stamping process is divided into cold stamping and hot stamping

2. Hot stamping can be divided into: ordinary flat hot stamping, three-dimensional hot stamping (commonly known as relief and concave convex hot stamping), and holographic positioning hot stamping.

The above is our sharing. Due to our high-quality products and excellent customer service, we have won customer support from all over the world. If you are interested in any of our products or would like to discuss custom orders, please feel free to contact us at any time.

Post time: Apr-14-2023